通常、より大きな形状や複雑な形状、より頑丈な合金には熱間鍛造が適していますが、非常に厳しい公差、優れた表面仕上げ、小型部品の大量生産が必要な場合には...

続きを読む

チュキオプロフィール

高品質の偽造ソリューション

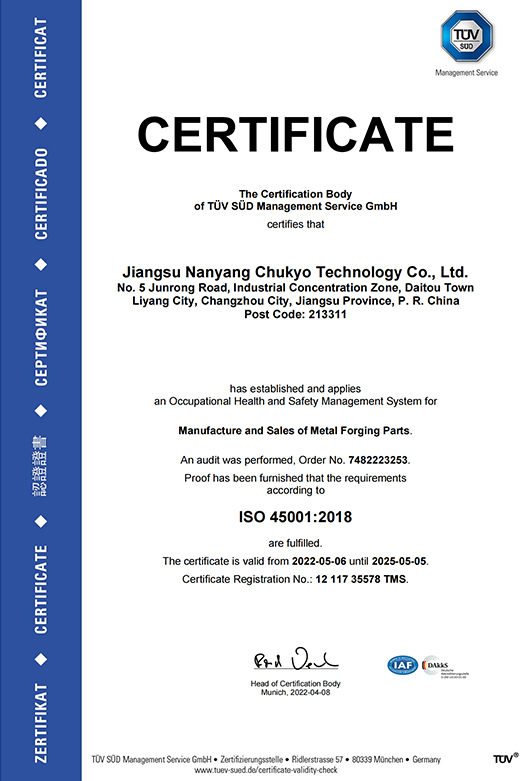

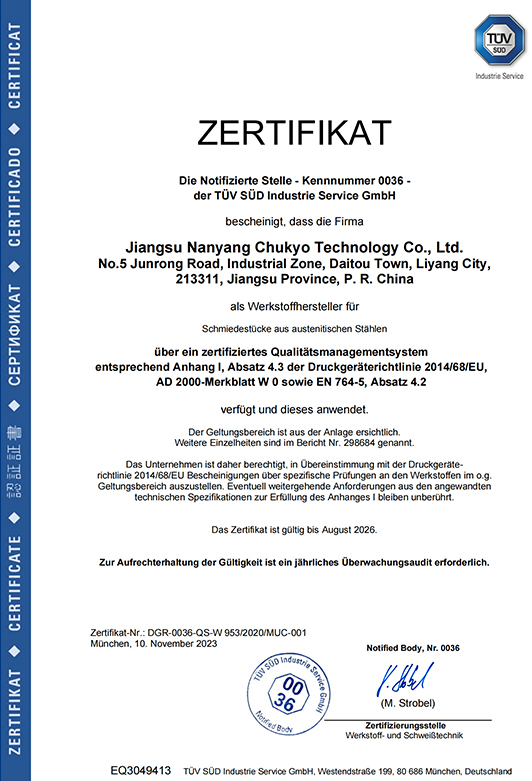

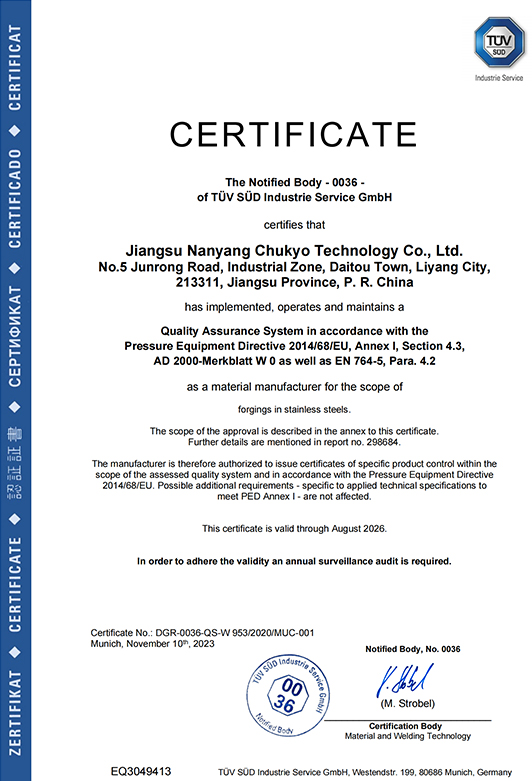

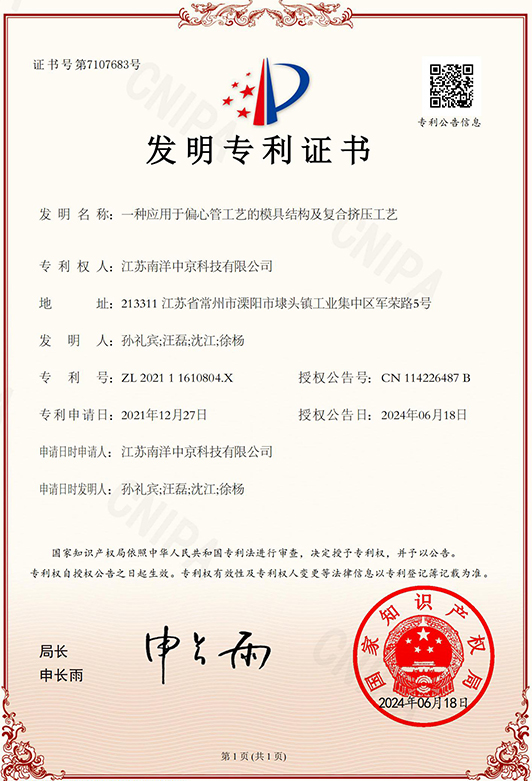

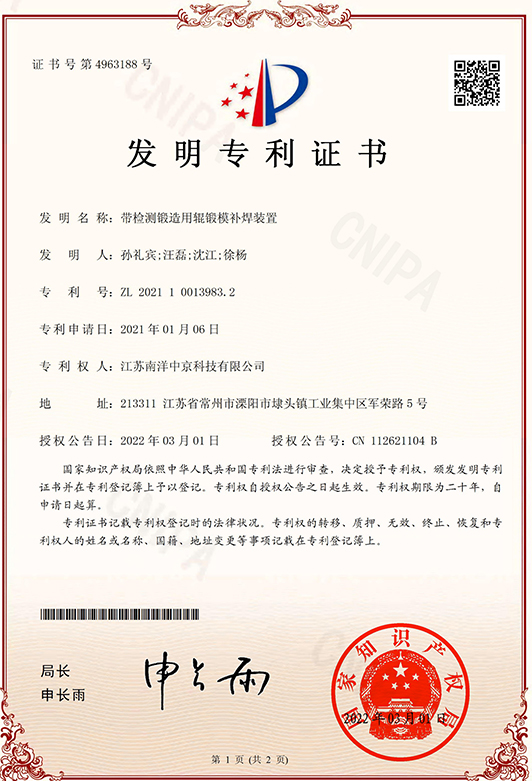

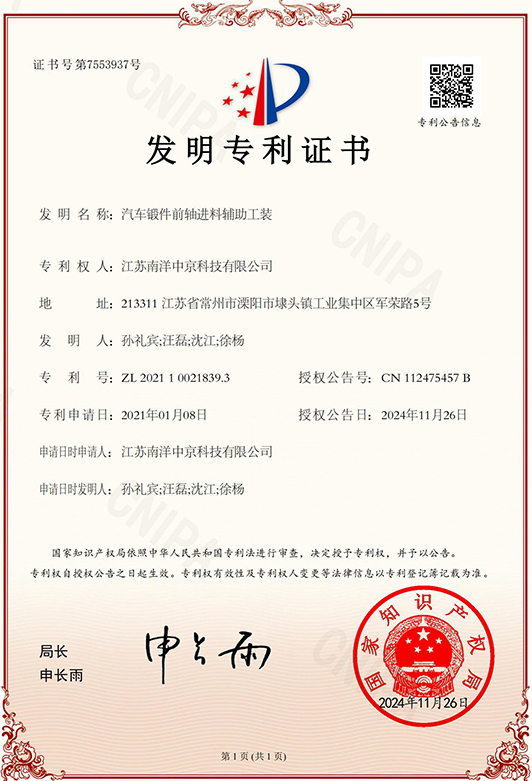

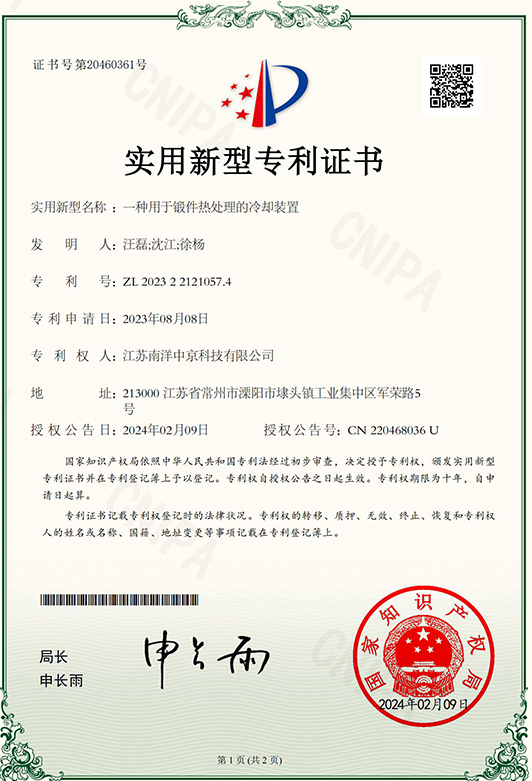

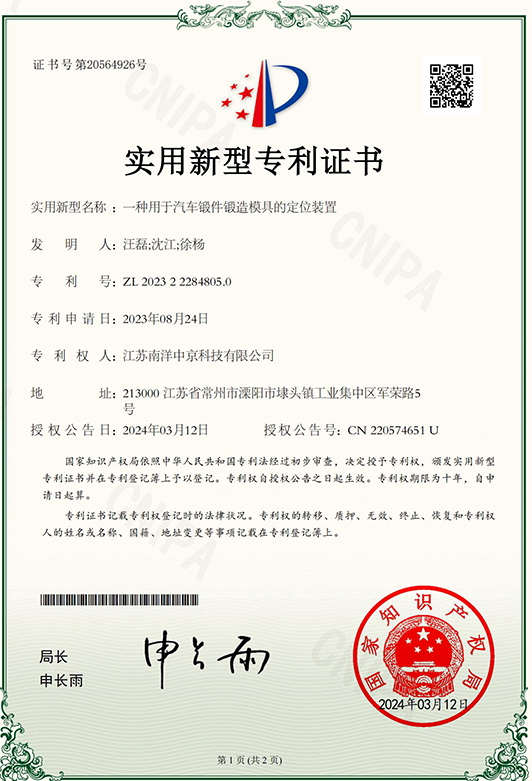

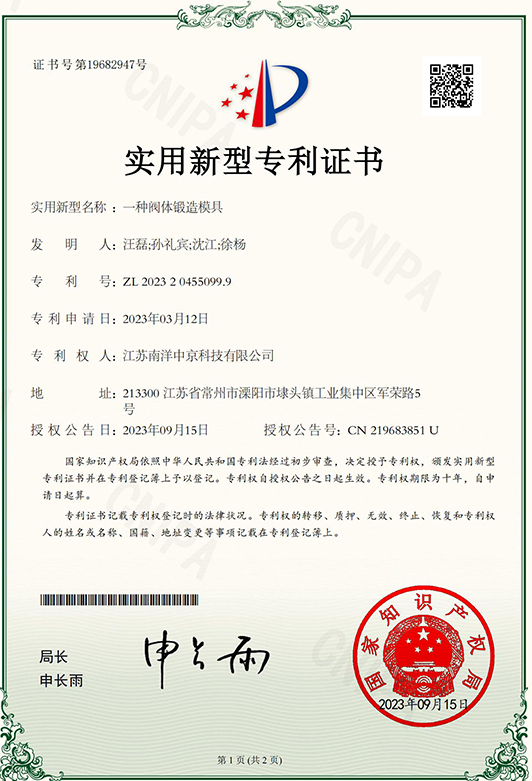

2017年に設立されたJiangsu Nanyang Chukyo Technology Co.、Ltd。は、20,000平方メートルの生産エリアを持つ42,000平方メートルの面積をカバーしています。 240人の従業員の現在の労働力と、カビの処理、のこぎり、鍛造、熱処理、加工、検査、包装をカバーする包括的な生産チェーンがあります。中国のメーカーとカスタムファクトリー。現在、同社は25,000トンの年間生産能力を持つ9つの生産ラインを所有しています。 5つの熱処理ラインと2つのステンレス鋼溶液機器が15,000トンの年間生産能力を備えています。 34の機械加工CNC旋盤と8つの機械加工センターで、年間300万個の作品を生産しています。当社の製品は、自動車、エンジニアリング機械、工業用計器、および鍛造部品で使用される流体機器業界で広く使用されています。

ニュース

-

-

海でも耐えるマリンシャフト鍛造 船舶用シャフトは容赦がありません。継続的なねじれを受けて動作し、アライメントやプロペラ負荷による周期的な...

続きを読む -

小型部品の鍛造が最も信頼できるのは、適切な鍛造ルート (冷間、温間、または熱間/クローズドダイ) を選択し、メタル フローに合わせて形状を設計し、公...

続きを読む -

直接の答え: ホウ砂は鍛造で何をするのか 鍛造では、ホウ砂は主に鍛造溶接用フラックスとして使用されます。 溶けてガラス状の層...

続きを読む -

鋳造と鍛造: 金属の変化 (そしてそれが重要な理由) 顧客が「鋳造か鍛造か」と尋ねるとき、彼らは通常、部品を過剰に指定することなく、現場...

続きを読む

業界の知識

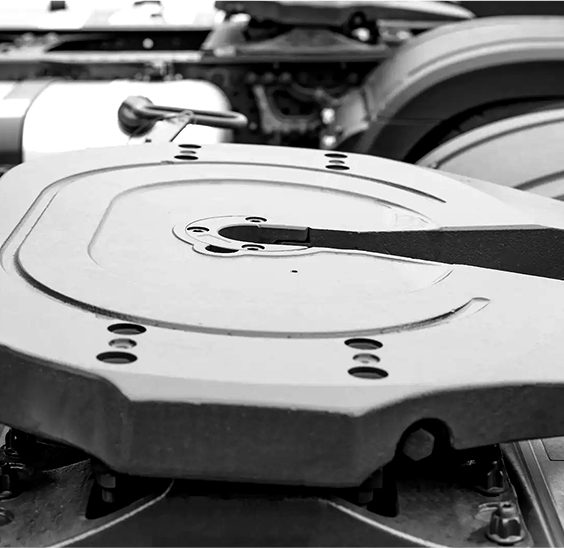

What specific parts of the fifth wheel traction seat are commonly forged, and why?

In the intricate web of components that make up a truck-trailer connection, fifth wheel traction seats stand as pivotal elements ensuring secure and reliable coupling. Amidst the array of manufacturing processes available, forging emerges as a cornerstone method for crafting certain components integral to these seats.

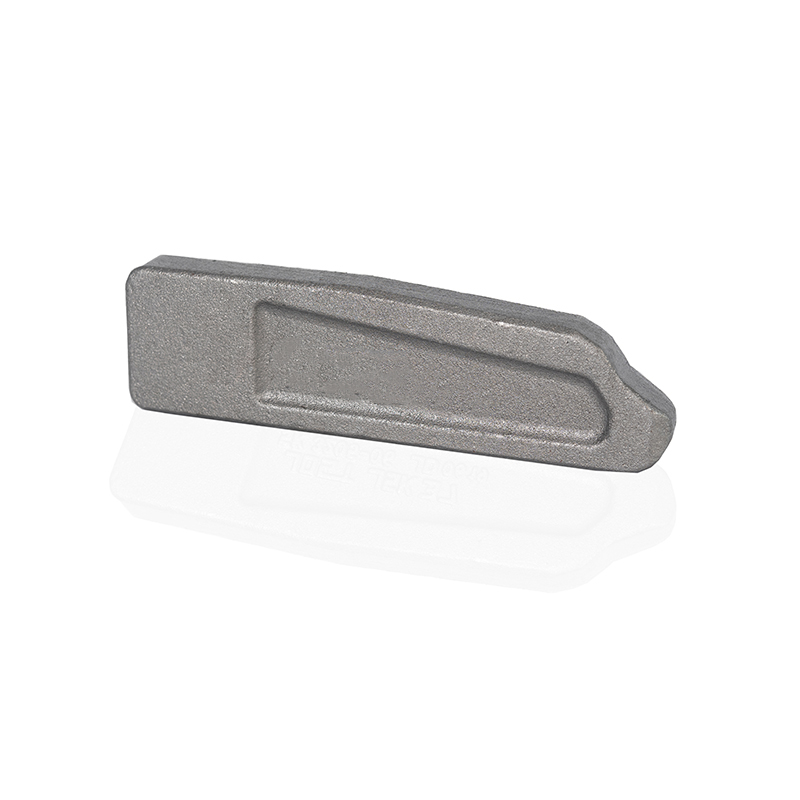

At the heart of the fifth wheel traction seat lies the kingpin, a cylindrical pin on the trailer that inserts into the fifth wheel. This component shoulders the weight and forces exerted during transportation, making its structural integrity paramount. Fifth Wheels Traction Seat Forging the kingpin confers unparalleled strength and durability, attributes indispensable for withstanding the substantial loads encountered on the road.

The forging process imbues the kingpin with a dense and uniform grain structure, fortifying it against fatigue and deformation. Such resilience ensures that the kingpin maintains its shape and functionality over prolonged periods of heavy use, safeguarding the integrity of the truck-trailer connection.

Complementing the kingpin is the fifth wheel plate, onto which the kingpin locks, providing the pivotal point of articulation between the truck and trailer. Given its role in distributing loads and facilitating smooth maneuverability, the fifth wheel plate demands robust construction. Forging emerges as the method of choice, offering unparalleled structural integrity and dimensional accuracy.

Forged fifth wheel plates boast superior strength and resistance to deformation, crucial characteristics for withstanding the dynamic stresses inherent in transportation operations. By subjecting the plate to the forging process, manufacturers ensure a reliable and secure connection between the truck tractor and its trailer, mitigating the risk of premature wear or failure.

In addition to the kingpin and fifth wheel plate, various supporting components contribute to the stability and functionality of the fifth wheel traction seat assembly. Brackets, mounting hardware, and reinforcement structures are commonly forged to meet the rigorous demands of the transportation industry.

Can forged fifth wheel traction seat components be repaired or refurbished, or are they typically replaced when damaged or worn?

In the realm of heavy-duty transportation, the fifth wheel traction seat serves as the linchpin connecting truck tractors to trailers, bearing the weight and forces inherent in hauling goods across vast distances. Crafted with precision and durability in mind, forged components within these traction seats are engineered to withstand the rigors of the road.

Repairing forged fifth wheel traction seat components hinges on several factors, foremost among them being the extent of damage. Minor surface imperfections or wear may be rectifiable through grinding or polishing techniques. However, if the damage extends beyond surface-level abrasions, such as cracks or deformation, more comprehensive repair measures may be necessary.

Forged components are renowned for their exceptional toughness and fatigue resistance, qualities that often render them more amenable to repair compared to components manufactured using alternative methods. The dense grain structure imparted during Fifth Wheels Traction Seat Forging enhances the material's ability to withstand stress and deformation, providing a solid foundation for repair efforts.

In instances where repair alone may not suffice, refurbishment offers a comprehensive solution for rejuvenating worn or damaged forged components. Refurbishment entails a meticulous process of inspection, repair, and restoration to return the component to its original specifications and functionality.

Before embarking on refurbishment, a thorough inspection of the component is imperative to evaluate its condition and ascertain the extent of necessary repairs. Non-destructive testing methods, such as ultrasonic or magnetic particle testing, may be employed to detect hidden defects or structural weaknesses.

Refurbishment of forged components often involves a combination of precision repair techniques, including welding, heat treatment, or machining. These processes are carefully executed to address structural deficiencies and restore the component's integrity while preserving its original material properties.

Throughout the refurbishment process, rigorous quality assurance measures are employed to verify that the refurbished component meets or exceeds industry standards for strength, dimensional accuracy, and performance. This ensures that the component is fit for service and capable of withstanding the demands of heavy-duty transportation operations.

While repair and refurbishment offer viable options for extending the service life of forged fifth wheel traction seat components, there are instances where replacement may be the most prudent course of action.

In situations where damage compromises the structural integrity of the component, replacement becomes imperative to prevent catastrophic failure during operation. Safety considerations must always take precedence in determining whether repair, refurbishment, or replacement is warranted.

The decision to repair, refurbish, or replace forged components also hinges on economic factors. A comprehensive cost-benefit analysis, weighing the expenses associated with each option against the anticipated benefits and longevity of the component, guides decision-making.

In the intricate web of components that make up a truck-trailer connection, fifth wheel traction seats stand as pivotal elements ensuring secure and reliable coupling. Amidst the array of manufacturing processes available, forging emerges as a cornerstone method for crafting certain components integral to these seats.

At the heart of the fifth wheel traction seat lies the kingpin, a cylindrical pin on the trailer that inserts into the fifth wheel. This component shoulders the weight and forces exerted during transportation, making its structural integrity paramount. Fifth Wheels Traction Seat Forging the kingpin confers unparalleled strength and durability, attributes indispensable for withstanding the substantial loads encountered on the road.

The forging process imbues the kingpin with a dense and uniform grain structure, fortifying it against fatigue and deformation. Such resilience ensures that the kingpin maintains its shape and functionality over prolonged periods of heavy use, safeguarding the integrity of the truck-trailer connection.

Complementing the kingpin is the fifth wheel plate, onto which the kingpin locks, providing the pivotal point of articulation between the truck and trailer. Given its role in distributing loads and facilitating smooth maneuverability, the fifth wheel plate demands robust construction. Forging emerges as the method of choice, offering unparalleled structural integrity and dimensional accuracy.

Forged fifth wheel plates boast superior strength and resistance to deformation, crucial characteristics for withstanding the dynamic stresses inherent in transportation operations. By subjecting the plate to the forging process, manufacturers ensure a reliable and secure connection between the truck tractor and its trailer, mitigating the risk of premature wear or failure.

In addition to the kingpin and fifth wheel plate, various supporting components contribute to the stability and functionality of the fifth wheel traction seat assembly. Brackets, mounting hardware, and reinforcement structures are commonly forged to meet the rigorous demands of the transportation industry.

Can forged fifth wheel traction seat components be repaired or refurbished, or are they typically replaced when damaged or worn?

In the realm of heavy-duty transportation, the fifth wheel traction seat serves as the linchpin connecting truck tractors to trailers, bearing the weight and forces inherent in hauling goods across vast distances. Crafted with precision and durability in mind, forged components within these traction seats are engineered to withstand the rigors of the road.

Repairing forged fifth wheel traction seat components hinges on several factors, foremost among them being the extent of damage. Minor surface imperfections or wear may be rectifiable through grinding or polishing techniques. However, if the damage extends beyond surface-level abrasions, such as cracks or deformation, more comprehensive repair measures may be necessary.

Forged components are renowned for their exceptional toughness and fatigue resistance, qualities that often render them more amenable to repair compared to components manufactured using alternative methods. The dense grain structure imparted during Fifth Wheels Traction Seat Forging enhances the material's ability to withstand stress and deformation, providing a solid foundation for repair efforts.

In instances where repair alone may not suffice, refurbishment offers a comprehensive solution for rejuvenating worn or damaged forged components. Refurbishment entails a meticulous process of inspection, repair, and restoration to return the component to its original specifications and functionality.

Before embarking on refurbishment, a thorough inspection of the component is imperative to evaluate its condition and ascertain the extent of necessary repairs. Non-destructive testing methods, such as ultrasonic or magnetic particle testing, may be employed to detect hidden defects or structural weaknesses.

Refurbishment of forged components often involves a combination of precision repair techniques, including welding, heat treatment, or machining. These processes are carefully executed to address structural deficiencies and restore the component's integrity while preserving its original material properties.

Throughout the refurbishment process, rigorous quality assurance measures are employed to verify that the refurbished component meets or exceeds industry standards for strength, dimensional accuracy, and performance. This ensures that the component is fit for service and capable of withstanding the demands of heavy-duty transportation operations.

While repair and refurbishment offer viable options for extending the service life of forged fifth wheel traction seat components, there are instances where replacement may be the most prudent course of action.

In situations where damage compromises the structural integrity of the component, replacement becomes imperative to prevent catastrophic failure during operation. Safety considerations must always take precedence in determining whether repair, refurbishment, or replacement is warranted.

The decision to repair, refurbish, or replace forged components also hinges on economic factors. A comprehensive cost-benefit analysis, weighing the expenses associated with each option against the anticipated benefits and longevity of the component, guides decision-making.